When it comes to modern manufacturing, few terms are as pivotal as "CNC meaning". Standing for Computer Numerical Control, CNC technology has revolutionized industries by offering unmatched precision, efficiency, and automation in machining processes. From automotive to aerospace and even healthcare, CNC machines have become an integral part of creating high-quality components with minimal human intervention. But what exactly does CNC entail, and why is it such a game-changer in today's industrial landscape?

In this comprehensive guide, we will explore every facet of CNC, delving into its meaning, operation, applications, and diverse benefits. We’ll also address common questions about CNC that often arise among enthusiasts and professionals alike. Whether you're a beginner keen to understand the basics or a seasoned expert looking to deepen your knowledge, this article is designed to provide valuable insights tailored just for you.

So, buckle up as we dive headfirst into the world of CNC. By the end of this guide, you’ll not only understand the CNC meaning in its entirety but also appreciate how this technology is shaping the future of manufacturing and beyond. Let’s get started!

Table of Contents

- What Does CNC Mean?

- How Does CNC Work?

- Types of CNC Machines

- Applications of CNC

- Benefits of Using CNC

- CNC vs. Traditional Machining

- What Industries Use CNC?

- Essential Components of CNC

- Common Materials Used in CNC

- What Software is Used in CNC?

- How to Maintain a CNC Machine?

- Future of CNC Technology

- How is CNC Different from Automation?

- Frequently Asked Questions

- Conclusion

What Does CNC Mean?

The term "CNC" stands for Computer Numerical Control. It refers to a technology in which computers are used to control machining tools and processes. Unlike manual operations where workers manipulate tools by hand, CNC technology automates these tasks through pre-programmed software instructions. This ensures high levels of precision, repeatability, and efficiency.

CNC machines can perform a variety of tasks, such as cutting, drilling, milling, and turning, with minimal human intervention. All it takes is a well-written program that specifies the machine’s movements, speed, and tooling paths. The result? Consistent, high-quality products that meet stringent industry standards.

At its core, CNC technology bridges the gap between human ingenuity and machine efficiency. Its impact spans countless industries, making it a cornerstone of modern manufacturing. But how does this advanced system actually work? Let’s break it down step by step in the next section.

How Does CNC Work?

What is the core principle of CNC?

The fundamental principle of CNC lies in automation. Through specialized computer software, CNC machines are programmed with specific instructions that dictate their operations. These instructions are input into the machine via a G-code or M-code, which tells the machine how to move, what tools to use, and how fast to operate.

Steps in the CNC process

- Design phase: The process begins with creating a design using Computer-Aided Design (CAD) software.

- Conversion to CNC code: The CAD design is then converted into a machine-readable language using Computer-Aided Manufacturing (CAM) software.

- Machine setup: The CNC machine is set up with the required tools and materials, ensuring everything is in place for the operation.

- Execution: The program is loaded, and the machine executes the operations as per the programmed instructions.

By leveraging this workflow, CNC machines can achieve unparalleled accuracy and speed, enabling businesses to meet demanding production schedules without compromising quality.

Types of CNC Machines

CNC machines come in various shapes and sizes, each designed to fulfill specific functions. Here are the most common types:

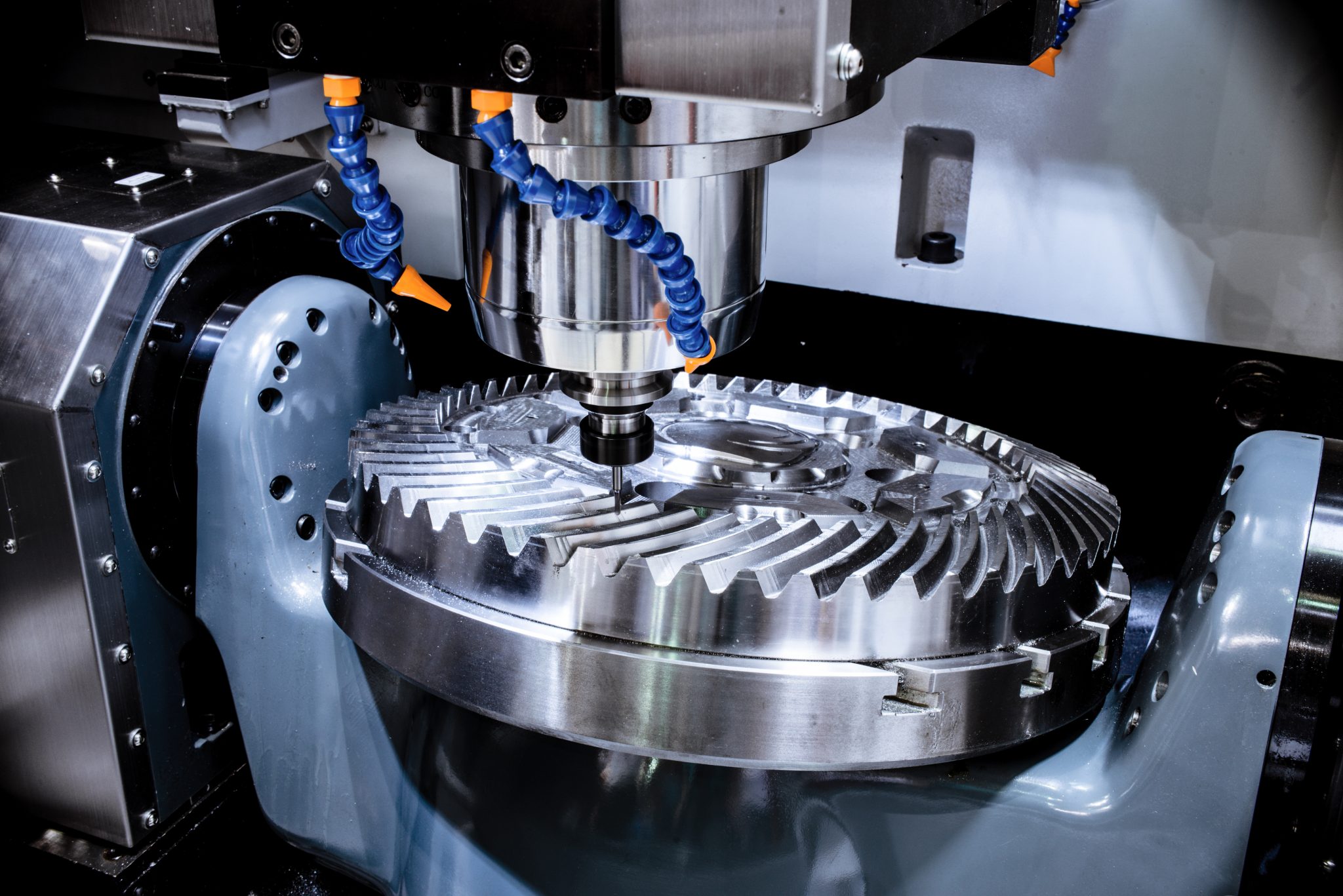

- CNC Milling Machines: Used for carving, cutting, and shaping materials into desired forms.

- CNC Lathes: Primarily used for rotating a workpiece against a cutting tool to create symmetrical shapes.

- CNC Routers: Ideal for cutting softer materials like wood, plastic, and foam.

- CNC Plasma Cutters: Used for cutting electrically conductive materials like steel and aluminum.

- CNC Grinders: Essential for precision grinding and finishing of surfaces.

Each of these machines plays a pivotal role in different industries, from furniture manufacturing to aerospace engineering. Understanding their unique capabilities can help you choose the right machine for your needs.

Applications of CNC

The versatility of CNC technology allows it to be used across a wide array of industries. Some of its most notable applications include:

- Automotive: Manufacturing engine parts, gears, and other components with high precision.

- Aerospace: Creating lightweight yet durable parts for aircraft.

- Healthcare: Producing surgical instruments and prosthetics.

- Consumer Electronics: Crafting intricate parts for smartphones, laptops, and other gadgets.

- Construction: Cutting and shaping building materials like stone and metal.

These applications highlight the indispensable nature of CNC machines in today’s industrial world.

Benefits of Using CNC

Why should industries adopt CNC technology? Here are some compelling reasons:

- Precision: CNC machines offer unmatched accuracy, ensuring every product meets exact specifications.

- Efficiency: Automated processes reduce production time and increase output.

- Cost-effectiveness: While initial costs may be high, CNC technology reduces labor and material waste in the long run.

- Consistency: CNC machines produce identical products, ensuring uniformity across batches.

- Flexibility: With the right programming, CNC machines can handle complex designs and diverse materials.

With such advantages, it’s no wonder CNC technology continues to gain popularity across industries.

CNC vs. Traditional Machining

What sets CNC apart from manual machining?

The primary difference lies in automation. While traditional machining relies heavily on human effort and skill, CNC technology automates the entire process, reducing the scope for errors and inefficiencies.

Key differences

- Accuracy: CNC machines offer superior precision compared to manual operations.

- Labor: Traditional machining requires skilled operators, whereas CNC minimizes human involvement.

- Speed: CNC machines complete tasks faster, meeting tight production deadlines.

Understanding these differences can help businesses make informed decisions about which technology to invest in.

Frequently Asked Questions

1. What is CNC meaning?

CNC stands for Computer Numerical Control, a technology that automates machining processes through computer programming.

2. How does CNC improve efficiency?

CNC machines reduce human intervention, increase speed, and ensure consistent quality in production.

3. What materials can CNC machines process?

Common materials include metals (steel, aluminum), plastics, wood, and composites.

4. Are CNC machines expensive?

While the initial investment is high, the long-term benefits like reduced labor costs and material waste make them cost-effective.

5. Can small businesses use CNC machines?

Yes, many CNC machines are designed for small-scale operations, offering scalability and affordability.

6. What industries benefit the most from CNC technology?

Industries like automotive, aerospace, healthcare, and electronics rely heavily on CNC for precision manufacturing.

Conclusion

In summary, understanding the CNC meaning goes beyond its technical definition. It represents a technological leap that is reshaping industries and setting new standards for precision, efficiency, and innovation. From its core principles to its wide-ranging applications, CNC technology is undeniably a cornerstone of modern manufacturing. As we continue to advance, the role of CNC will only grow, pushing the boundaries of what’s possible in the industrial world.

For further reading and resources on CNC technology, consider visiting Autodesk, a leading authority in CAD and CAM software solutions.

Article Recommendations